Collaborated with_Chinh Nguyen, Dan Opera

Precedent_Chuck Close

This studio was intended to unite the focused material and fabrication aspects of wall section design through an extended and in depth investigation of a composite material system that embodies a range of performance types, material expressions and technical interface.

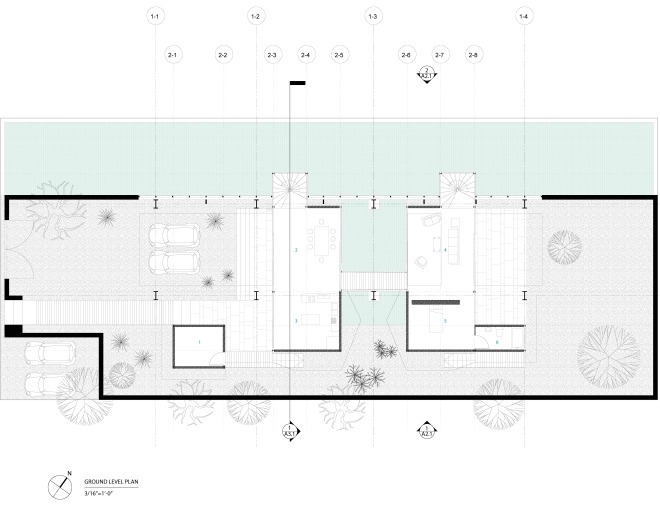

We were interested in building intelligence into pixel construction through different performative layers to create visual ambiguities from both exterior and interior. The site is currently active as a Jewish community center along Olympic Blvd LA, we replaced the North and West facade with our design, which appears as two bands of changing hue at day time and two lurking bands of light at night.

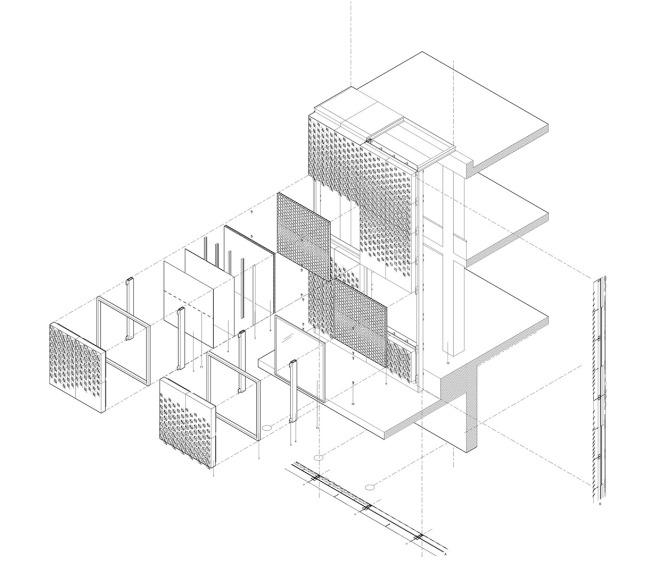

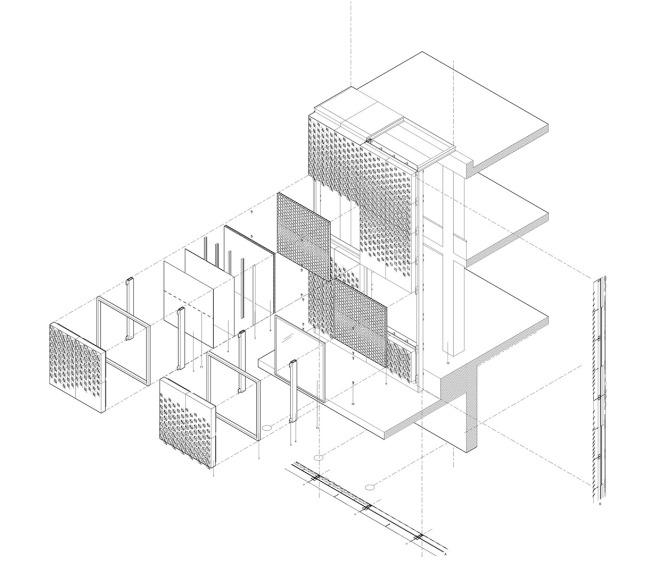

A primary intention of the project was to synthesis the conventional discreet set of performative layers in wall section, such that equal emphasis is placed on the investigation and exploitation of these layers. And the construction of a half-scale prototype at the end testified the organization of the material, geometric, technical and structural ingredient that combined to form a building envelope with synthesized and demonstrated effect.

Inspiration was sought from other disciplines, especially works of painter Chuck Close, which embeds pixels within pixels, in terms of space, reflectiveness and color. We juxtaposed different hues assigned to each pixel layer to create an aura with painterly coloring strategy.

Color choices were limited down to five, and broken down into spray-painting templates to apply colors layer by layer, similar to screen printing technique. From a distance, there are obvious shifts in hue, but if one stands at the underside of the pixels, there is an explosion of vibrant and juicy colors which contrast each other.

These 4’ by 4’ panels are milled from aluminium sheets. The two layers of metal pixels are each rotated to a different degree (inner pixel: 90deg, outer pixel 45deg), spatially revealing the performative layers behind the metal panels.

The interior reading was filtered through the flat double interior panels with hexagonal cut-out and shifted gradient, adding visual ambiguities to the color explosion from the back side of exterior aluminium panels.

In terms of the overall pattern, the pixels are placed within a field generated by simple attractor curves, but when the inner pixel geometries juxtapose with the outer pixel geometries, bands of unpredictable shades and gradients are produced.

Fifty percent of the facade has 4‘by8’ glazing between the interior and exterior panels, the other fifty has milled 4‘by8’ foam insulation protruding from between the panels, through interior panels to indoor. The designed pattern and thickness gradient can be seen and touched form indoor.